A detailed guide on how to overcome ink flow problems and get your printer up and running for seamless productions.

TexJet echo2 ink flow system

First of all, in order to approach ink flow related problems, you must have all the information on how the ink flow system operates. This means that you need to know the parts it consists of and purpose of each part. So, lets brake down how the ink flow system works:

There are two types of ink cartridges that can be installed on the TexJet echo2 printer. The most common are sealed cartridges, where the ink is protected inside a pouch and are replaceable once emptied. The second option is user-refillable cartridges, which can be refilled multiple times with bulk ink.

There are two types of ink cartridges that can be installed on the TexJet echo2 printer. The most common are sealed cartridges, where the ink is protected inside a pouch and are replaceable once emptied. The second option is user-refillable cartridges, which can be refilled multiple times with bulk ink.

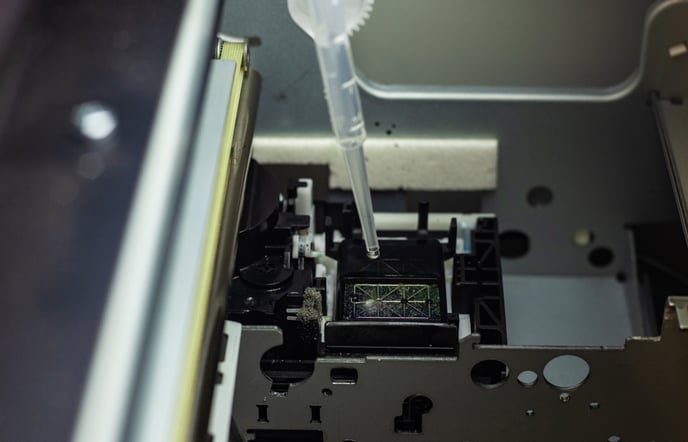

TexJet echo2: Refillable ink cartridges filling procedure

Both cartridge types are pressurized. A pressure pump supplies the air that fills the cartridges and this way, the ink is pushed into the ink system tubes. When the ink has filled the entire ink flow route, then it ends up at the dampers’ assembly that is positioned on top of the printhead. The dampers are then connected with the printhead channels and that is how the ink flows all the way into the nozzles.

The capping station is where the printhead “rests” after printing. When the printhead is locked at the cap, the nozzle plate is sealed at the capping station airtight. This way, the nozzles are protected. During cleanings, the cap pulls ink from the head surface and through the capping station tubes the ink ends up at the waste tank.

How to efficiently resolve ink flow related issues

STEP 1. Regulate the environmental conditions

DTG printers preferably operate at room temperature (10- 30°C) and between 30-70% humidity levels. Ideally, 20°C and 55% humidity. Operating the printer in inappropriate conditions can cause a change in the consistency of the inks and eventually, may end up blocking the ink flow system, leading to possibly clogged printhead nozzles. To avoid possible ink flow issues, due to ambient conditions, you can always check the temperature of your workspace and regulate the humidity levels with the use of a humidifier.

DTG printers preferably operate at room temperature (10- 30°C) and between 30-70% humidity levels. Ideally, 20°C and 55% humidity. Operating the printer in inappropriate conditions can cause a change in the consistency of the inks and eventually, may end up blocking the ink flow system, leading to possibly clogged printhead nozzles. To avoid possible ink flow issues, due to ambient conditions, you can always check the temperature of your workspace and regulate the humidity levels with the use of a humidifier.

Importance of humidity & temperature in my workspace

Note: TexJet echo2 is equipped with special sensors that monitor the ambient environmental conditions of your workspace and alert you for changes that may affect your results. The humidity levels and the temperature are always displayed in the Platen Control Panel once the printer is opened. You will also see them in pop-up messages, when the sensors detect an unwanted change, out of the recommended values.

STEP 2. Maintain properly the capping station, wiper & printhead

Make sure that you correctly perform the daily, weekly and monthly maintenance routine. If the maintenance on those parts haven’t performed properly, it means that dried ink and fibers will be gathered. Regarding the capping station, if its rubber surroundings are not cleaned properly, the ink build-up can cause an inaccurate sealing of the printhead and thus, resulting in nozzle dryness. The wiper should also be cleaned daily after printing, as it is responsible for wiping the bottom of the printhead, during production to keep her clean. The printhead bottom can gather fibers and dried ink, risking this way nozzle blockage. Hence, you must carefully clean its surroundings every day after your production with a swab.

TexJet echo2: Daily & weekend maintenance guide

TexJet echo2: Six-month maintenance procedure

TexJet echo2: Monthly maintenance guide

Caution: During printer maintenance the printhead must NOT be unlocked for more than 5 min.

If you have performed the maintenance procedures according to the instructions and still having trouble getting a proper nozzle check, perform a Heavy Head Cleaning from the Printhead Control Panel and then, a Nozzle Check to see the condition of the nozzles. If there is still evident nozzle loss, apply some cleaning solution and lock the printhead on the capping station for at least 10 min, in order to soak. Then, perform a Heavy Head Cleaning and check the nozzle condition.

If you have performed the maintenance procedures according to the instructions and still having trouble getting a proper nozzle check, perform a Heavy Head Cleaning from the Printhead Control Panel and then, a Nozzle Check to see the condition of the nozzles. If there is still evident nozzle loss, apply some cleaning solution and lock the printhead on the capping station for at least 10 min, in order to soak. Then, perform a Heavy Head Cleaning and check the nozzle condition.

For a more severe clogging phenomenon, you can try applying some Isopropyl Alcohol (IPA) to the capping station and leave it maximum for 10 minutes. Then, perform a Heavy Head Cleaning from the Printhead Control Panel and a Nozzle Check to see the condition of the nozzles. Don’t leave the IPA for a longer time as the rubber surroundings of the capping station are sensitive to it and can cause their degradation.

Warning: Don’t proceed with further cleanings if the problem has not been fixed. Heavy cleaning is very powerful, resulting in negative pressure on the printhead if done multiple times.

STEP 3. Perform correctly the Auto height adjustment

Sometimes, if you use a garment with a lot of fibers those can rise up during printing, especially in a very humid environment. These fibers can reach the printhead bottom and cause nozzle issues. This is why is vital to perform correctly the auto height adjustment feature that all TexJet® printers are equipped with. Additionally, you should place correctly your garment at the printer’s platen and use the adjustable frame system or fabric glue to make sure your fabric is kept stable during printing.

TexJet echo2: Auto height adjustment feature & why it is important

Tip: In case of very fibrous fabrics, you can lower the platen to achieve a safe distance from the printhead and opt for Uni-directional printing, in order to maintain the printing quality.

STEP 4. Replace the ink cartridges and check the ink batch numbers

If there are whole ink channels missing, replace the ink cartridge(s) and in case of user-refillable cartridge fill with fresh ink. Perform a Heavy Head Cleaning and check the Nozzle test. Make sure that the inks you are using have not expired, as they may cause ink flow issues.

If there are whole ink channels missing, replace the ink cartridge(s) and in case of user-refillable cartridge fill with fresh ink. Perform a Heavy Head Cleaning and check the Nozzle test. Make sure that the inks you are using have not expired, as they may cause ink flow issues.

Note: Keep in mind that the nozzle loss during printing can occur due to incorrect maintenance or because the printhead is not sealed properly on the capping station.

STEP 5. Get professional help

If the issue insists, please reach out to a qualified technician or your local dealer for help. You can also come in touch with our support team, by filling out the form: https://polyprintdtg.com/support/

To get a more accurate and prompter response, please include the following in your issue report:

- Nozzle test picture

- Capping station picture with wiper out

- Printhead bottom surface

- Ink batch numbers

Warning: Don’t try anything that can put your machine at risk, as you may cause further damage and invalidate your printer’s warranty.

-1.png?height=120&name=Polyprint%20Logo%20(Dark)-1.png)