An introductory guide on textile types that are most commonly used in the dtg applications.

Fabrics are the corner stone of successful dtg printing. They are like an artist’s canvas, if the canvas is not of good quality, it may ruin the artist’s creation. In a similar way, it is important to choose the right fabric to bring your prints to life with DTG printing and produce a comfortable garment that holds up to wear and tear.

Types of fabrics

Fabrics fall into three categories: Natural, Synthetic and Blends. Not all types of fabric are suitable for dtg printing, so let’s take a closer look.

Natural fabrics

Traced back to 1500 BC, these fabrics are produced from natural resources (e.g. plants or animals). Most common are cotton, linen, hemp, bamboo and wool.

Synthetic fabrics

Synthetic fabrics are man-made. Nylon was the first fully synthetic fiber that developed by Carothers at DuPont’s lab in the 1930s. Synthetics are well known for their elasticity and are mostly preferred for sportswear. The most common are Acrylic, Nylon, Polyester, Lycra and Viscose.

Blends

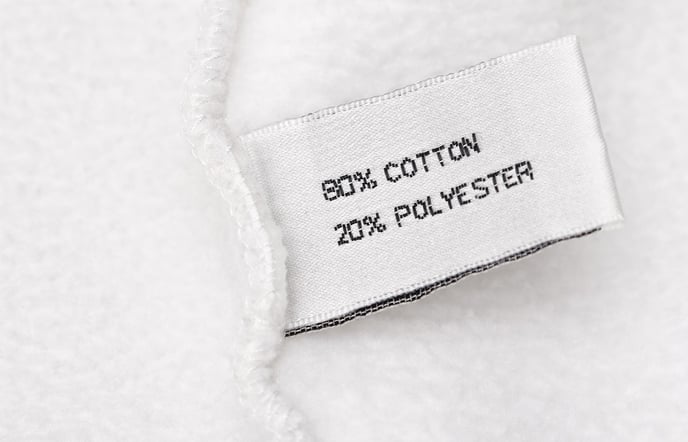

The combination of cotton and synthetic fibers is called a blend. There are multiple combinations (e.g. Cotton/Polyester, cotton/lycra). The most known blend is the poly-blend (polyester + cotton), this fabric is lightweight, wrinkle free and breathable. This strong, but soft to the touch fabric leads the way to multiple applications.

Suitable fabrics for DTG printing

DTG printing is recommended for complex designs, with sharp details and multiple color variations. Dtg printers use water-based inks, hence best results occur with natural fabrics, as they have the tendency to absorb liquids. The outcome is vibrant colors that are strongly fixated into the fibers resulting in high wash endurance. Synthetic fabrics, on the other hand, repel water as they are composed from plastic.

The most suitable textiles for DTG printing that are considered: Cotton, Combed Cotton, Organic Cotton, Linen, light-colored polyester and blends.

Cotton

Cotton is an affordable, strong material that is soft to the touch. This fabric easily absorbs water-based inks, making dtg printing a walk in the park. Admittedly, 100% cotton fabrics are the king. But your end result may also depend on the fabric’s consistency. Thicker materials absorb more ink, leading to vibrant colors and long-lasting prints, in contrast to thinner materials. In general, there are various cotton types, and their quality may depend on the manufacturer. For the best possible print, you should choose smoother, softer fabrics.

Regular cotton

This type of cotton is made by taking the fibers and twisting them together to make yarn that afterwards is woven together to make the end-material. Regular cotton is affordable and of lower quality which means that is very popular among manufactures of fast fashion.

Organic cotton

This environmentally friendly cotton is grown without the use of toxic and persistent pesticides and synthetic fertilizers. This technique doesn’t use toxins, allowing the soil to maintain its fertility. It is considered one of the most sustainable choices for dtg printing.

This environmentally friendly cotton is grown without the use of toxic and persistent pesticides and synthetic fertilizers. This technique doesn’t use toxins, allowing the soil to maintain its fertility. It is considered one of the most sustainable choices for dtg printing.

Ring-spun cotton

Twisting and thinning the cotton strands results into incredibly fine into soft ropes of cotton fibers. Ring-Spun cotton fabrics are lighter, softer, more durable and last longer. They are also more expensive as more effort is required in their production, but provide a higher quality product. They offer a very smooth surface that when printed, provides a vivid and sharp image. Ring spun cotton tees are recommended for fashion and “boutique” printing.

Combed cotton

Before the yarn is made, the cotton is “combed” which means it brings all the fibers parallel to each other and removes all the shorter fibers. By removing the short fibers, only the longest finest remaining fibers remain which gives the combed cotton it’s smooth feel and high sheen. In addition, because the fibers are longer, they are stronger and less likely to break leading to a longer life of the product.

Linen

Made from the flax plant, linen in known for absorbing moisture. Rougher than cotton, it wrinkles easily. Maybe not the most popular choice for t-shirts, but it is often used in shirts, pants and jackets.

Polyester

Polyester is a synthetic fiber commonly used in dye sublimation. Easy to wash, without requiring ironing you usually find it in athletic wear. Generally, polyester repels water-based ink used in dtg printing. Dye migration is a phenomenon that occurs when dye from polyester fabric bleeds into the ink that is printed on the garment. For that reason, in order to print on polyester, you will need prior to pretreat the fabric. The rule of thumb is that light-colored polyester is more suitable for dtg printing, as the inks perform better and don’t disappear into the fabric as in the case of dark-colored polyester.

Precoating and Polycoating liquids textile applications

Poly-Blends

If unable to use 100% cotton fabrics, you could always try cotton blends 80% – 20%, 70% – 30%, 50% – 50%. Generally, the more cotton contained in the fabric, the better the end result. The most common blend is the poly-cotton blend (cotton + polyester). This fabric is breathable, lightweight, strong and wrinkle free due to the polyester. Many t-shirts are made of a poly-cotton blend, but not all blends can be printed with success, as the amount of polyester will dictate the success of the print. Generally, the higher the percentage of cotton in the mix, the better the print.

If unable to use 100% cotton fabrics, you could always try cotton blends 80% – 20%, 70% – 30%, 50% – 50%. Generally, the more cotton contained in the fabric, the better the end result. The most common blend is the poly-cotton blend (cotton + polyester). This fabric is breathable, lightweight, strong and wrinkle free due to the polyester. Many t-shirts are made of a poly-cotton blend, but not all blends can be printed with success, as the amount of polyester will dictate the success of the print. Generally, the higher the percentage of cotton in the mix, the better the print.

Eco-friendly solutions

You may also find in the vast fabric market the latest eco-friendly fabric trends. You can now print on bamboo or hemp.

Bamboo

Breathable and absorbent, bamboo fabric is soft and feels like silk. This hypoallergenic fabric is antimicrobial and has UV blocking properties.

Hemp

Hemp is a durable and soft fabric that has antimicrobial and UV blocking properties and can retain warmth well. It is suitable for people with allergies and stands as a new proposal for the apparel printing market.

Whatever fabric you choose to bring your creations to life, the key is to always experiment, to find the best solution for you!

-1.png?height=120&name=Polyprint%20Logo%20(Dark)-1.png)