The main mechanical and electronic components of the TexJet dtg printers that contribute to delivering the utmost printing quality.

In Direct-to-Garment technology there are a lot of variables that determine the quality of the end-product, the core of them being attached to the dtg printer itself. TexJet dtg printers are designed and manufactured in a specific way that allow the user to achieve the best printing quality possible. This happens mainly, due to the characteristics of the print engine itself along with a precise and attuned motion of both the printhead and the platen.

Printhead

The technical characteristics of the printhead such as the ink drop size, the spectrum of the drop size (the range that nozzles can simultaneously spray during the printing process) and the printhead gap are of great importance when it comes to the quality of the final product. The printhead of TexJet printers has a minimum ink drop size of 3pl, one of the smallest in the DTG industry, allowing the user to achieve scalpel-sharp details. The variety of drop size that the nozzles can spray fluctuates at a range from 3 to 22 pl and has a huge impact. As apart of increased sharpness, it provides even ink coverage without any gaps. In addition, the printhead is set at a gap of 2.5 mm from the media that allows precise printing on uneven surfaces, such as shoes or textile of lower quality. This feature also prevents the garment’s fibers from coming into contact with the printhead’s surface, which may affect its condition and by extend the printing quality.

Precise platen height adjustment system

In order to have a printed image of excellent quality with vibrant colors and sharp details, the correct distance between the printhead’s nozzles and the fabric’s surface must be achieved. TexJet printers feature build-in optical sensors and operate an automatic motorized elevation movement, ensuring that the height adjustment will be precise, due to the fine steps of the motor. This will result in a safe and accurate distance between the printhead and the garment, regardless of the media thickness. In that way, the printhead performs at the maximum level, while it is protected from being too close to unwanted fibers.

Auto height adjustment feature on TexJet shortee2 & why it is important

Auto height adjustment feature on TexJet echo2 & why it is important

Platen motion controller

The synchronous motor that all TexJet dtg printers are equipped with, increases stability of the platen movement during the printing process, as it eliminates any possible vibrations. This allows the platens’ smooth movement, which is precisely attuned with the printhead’s, contributing this way in the quality of the printed image.

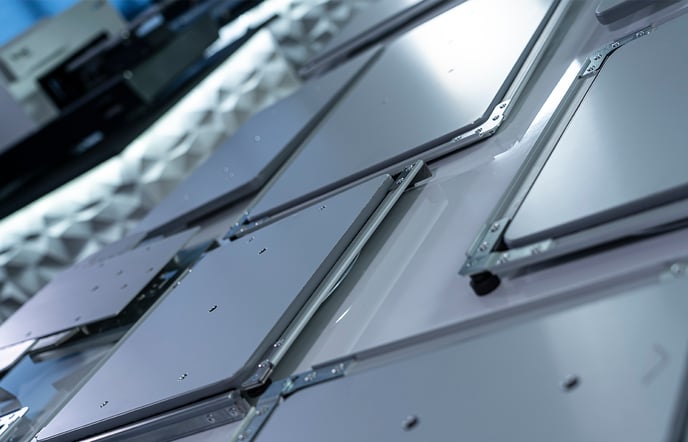

Platens and their frames

TexJet dtg printers offer a variety of platens that you can choose from depending on the size of the garment and the application that is targeted. Different kind of platens with the help of either an adjustable frame or a fabric glue, ensure that the garment stays flat during the printing process, offering a smooth, printable surface that will ensure premium quality. The platens are designed in a specific way in order to cover most of the common DTG applications, but also some of the more demanding ones, like shoe printing. Polyprint also offers the option of custom made platens, apart from the ones that are available, in case of need.

-1.png?height=120&name=Polyprint%20Logo%20(Dark)-1.png)