How to maintain your NG printer at the end of each production day. The correct process for cleaning the wiper blades, capping station, and printheads.

STEP 1

At the NG Touchscreen, go to Menu. Tap on Maintenance. Activate the Disable/Enable Cover Sensors toggle button.

STEP 2

Open all three front covers to have access to the Head Carriage for maintenance reasons.

STEP 3

At the NG Keypad press the Head Left button to release the carriage from suction. Press continuously the Head Left button to move the head at the far-left side of the printer, right above the maintenance mirror.

STEP 4

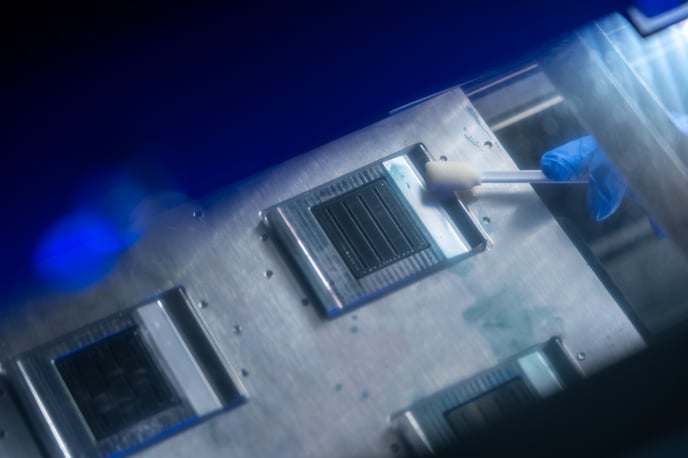

Looking at the maintenance mirror, with a swab wet in cleaner, start cleaning the printheads’ Nozzle Guards.

Looking at the maintenance mirror, with a swab wet in cleaner, start cleaning the printheads’ Nozzle Guards.

Caution: Be careful NOT to touch the mirrored surface of the printheads, as this is where the nozzles are.

STEP 5

Back at the capping station, use the swab to clean the rubber surroundings of the caps.

Back at the capping station, use the swab to clean the rubber surroundings of the caps.

STEP 6

Fill with cleaning solution the caps.

STEP 7

Close all open covers.

STEP 8

At the NG Keypad press the Enter button, so the carriage moves back to the capping station and seals.

STEP 9

Wait about 2 minutes, so the cleaning solution acts and then perform a Weak cleaning cycle.

STEP 10

On the NG Touchscreen go to Menu. Tap on Power ON/OFF. Select Printer so the printer shuts down.

STEP 11

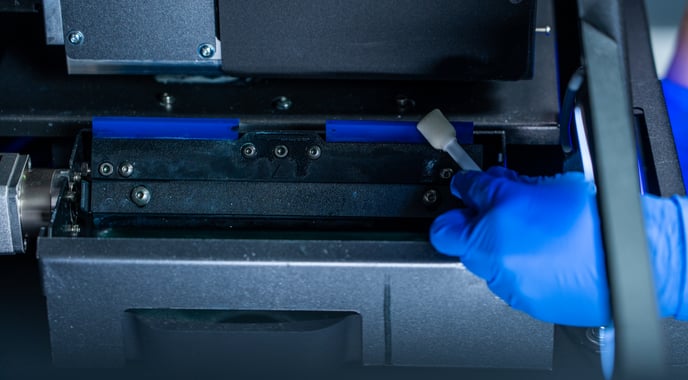

Clean the Wiper Blade System. With your hand, turn the mechanism to bring the blades upwards. With a swab clean them from ink.

Clean the Wiper Blade System. With your hand, turn the mechanism to bring the blades upwards. With a swab clean them from ink.

STEP 12

Once finished, turn the mechanism again, so the blades can pool into the maintenance liquid. Fill the tank with extra distilled water if necessary.

STEP 13

Close all covers you opened for maintenance and Enable the Cover Sensors again for safety.

STEP 14

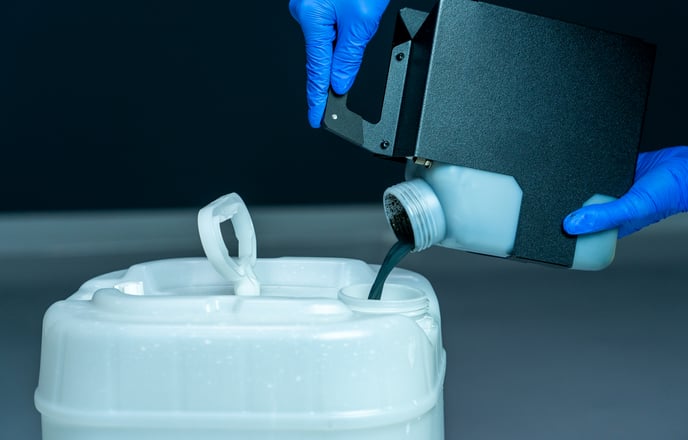

Empty the Maintenance Tank. Check the ink levels and refill if necessary.

Empty the Maintenance Tank. Check the ink levels and refill if necessary.

STEP 15

Check the ink levels and refill if necessary.

Note: If you are going to leave the printer idle for more than two days, for example the weekend, then you can put some cleaning solution on the caps, so the heads are pooling during this time.

-1.png?height=120&name=Polyprint%20Logo%20(Dark)-1.png)