Here follows an overview of the financial aspect that comes with running a DTG printing business in terms of funding, operating costs and profit.

What should an operator expect when entering the world of DTG printing? What are the main funding requirements? What are the regular operating & maintenance costs and what is the most common revenue stream? Read on the attempt to answer these questions as accurate as possible.

DTG Printer

First and foremost comes the printer! Market research is essential before purchasing the right DTG printing machine that will fit the business model perfectly and will make it profitable. Along with the printer comes the surrounding & supportive equipment that is purchased respectively with the type of jobs/orders the business is taking on.

Main differences & similarities of TexJet DTG printers

Pretreatment equipment

Pretreating the garments (especially the dark colored cotton shirts) is a crucial step for the proper printing outcome. To pre-treat, there are 2 options:

- When the volume of production is medium to high and on, a pretreatment machine is recommended; these tend to cost among 2K and 5K.

- If the business model is based on accepting low quantity order and the production volume is small, then manual pre-treating with a spray gun of around 100 EUR is advised. Still, not the optimized solution in terms of eco-friendliness and consistency, but it makes no sense investing on a machine when the daily production is 5 to 10 pieces.

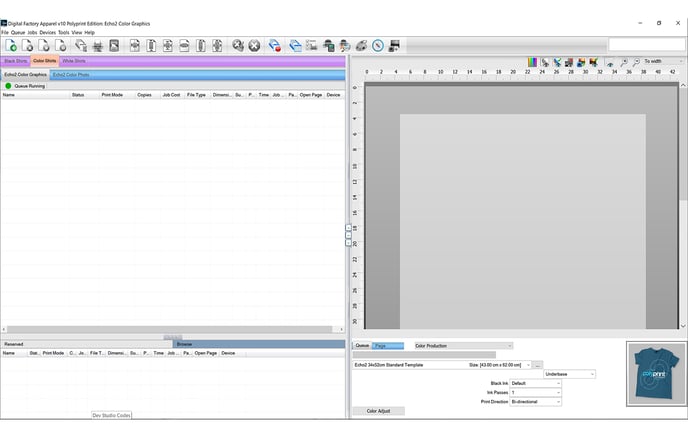

RIP Software

To operate with a printing machine, one must use a RIP software. Most printers come with a default program, however, there are additional and customized solutions in the market that will enhance the printing workflow and output; the value of such software solutions is usually around 1K. Not to mention a reliable PC/laptop the possession of it, is taken for granted.

To operate with a printing machine, one must use a RIP software. Most printers come with a default program, however, there are additional and customized solutions in the market that will enhance the printing workflow and output; the value of such software solutions is usually around 1K. Not to mention a reliable PC/laptop the possession of it, is taken for granted.

Curing equipment

Curing the garment is of great significance at every stage of the printing process. Before pretreating, after pretreating and after printing, the right fixation solution is needed. Most businesses in the field are using a heat press (usual cost is between 1K and 2K) and when business is scaling up, a conveyor dryer (starting from 4K) is suggested.

Curing Equipment in DTG: Heat Press vs Oven Dryer

Note: When business is scaling up, the option to expand the fleet of printers is most common. In that case, a conveyor dryer can be really helpful while setting up a DTG ‘pod’ (multi-printer setup) around it is highly effective.

All of the above are usually acquired by brands’ official distributors (dealers); the overall equipment can be paid in cash or be financed with a program that serves both parties. Based on the above, an initial investment starting from 18K makes perfect sense and inserts the business into the DTG printing market with high profit potential.

What are the regular expenses in a DTG printing business?

Following the initial investment and the funding of the business, it is the operational costs that will determine the Return-of-Investment timeframe and the overall profitability.

Factors that affect the DTG business running costs:

- Blank garments cost: The quality of the garment strongly affects the printing result. This said, it is advisable operators use the right textile quality in shirts, usually purchased from 2 euro per piece and on in bulk.

- Ink cost: In general terms, the cost of DTG inks is high. The inks are typically crafted for one specific manufacturer's printers and can come in sealed cartridges or in bulk for refillable ones depending on each ink delivery system. Typical cost per liter is between 150 EUR to 350 EUR, meaning that for a typical CMYKW DTG printer (with two white inks), there may be 1K worth of ink in the printer at any given time and may cost 300 EUR to 400 EUR a month to run for small to medium volumes of production. This also depends on the image size and the RIP settings.

How to set up and use the cost calculator feature in Digital Factory Apparel Polyprint Edition v10

Tip: DTG ink has certain shelf life, so there is no option to buy it on sale and save it for later.

- Pretreatment solution cost: Pre-treatment liquid is usually sold in the market from 15 EUR to 30 EUR per liter and each liter delivers around 40 - 50 pieces of garment, either a machine or a spray is used. Doing the math, it is easy to calculate the cost of pre-treatment at every stage of the business model.

Pretreater Pro: How do consumption counters work - Printer maintenance costs: To keep a machine running effectively, maintenance is definitive. In everyday routine, this includes the cleaning liquid, which is of minor cost & the ink consumption. Some printers come with auto cleaning, which secures the life of the printer but at the same time can be extra costly because of the high ink waste. Over time, the machine requires spare parts & consumables replacement; e.g. a DTG printhead must be replaced every 10K prints or so. On top of the above come the service costs since there are issues that require on-site settlement by support technicians.

TexJet printers: Ink consumption during cleanings

- Labor cost: This really depends! Mostly on the business type, which affects the volume of production. It is further dependable, either there is an e-shop running separately, either the print designs are made in-house, either the business attends promotional events etc. In any case, any tax liabilities and workstation costs must be taken into consideration.

What are the regular earnings?

The more shirts a business sells, the more revenue it makes. Considering that DTG printing allows high customization levels, the price of the end-product can also scale up high. This means that shirts can be at a price of 15 EUR to 25 EUR depending on the customer type and consequently, the revenue stream(retail/wholesale oriented). Having said that, always make sure that the garment color is considered upon pricing (separate light from dark shirts).

To sum up, one must take all the above into account before jumping into the DTG printing market. Initial investment, operational costs and most specifically cost per print should be calculated in regards with a potential gross profit. In that way, calculations upon turnaround times & Return of Investment (ROI) are safely achieved but the main factor to determine the success of the venture, is to decide what kind of businesses are on target!

Initial Investment: What to consider when starting with dtg & how can I estimate my budget?

-1.png?height=120&name=Polyprint%20Logo%20(Dark)-1.png)